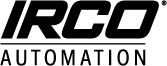

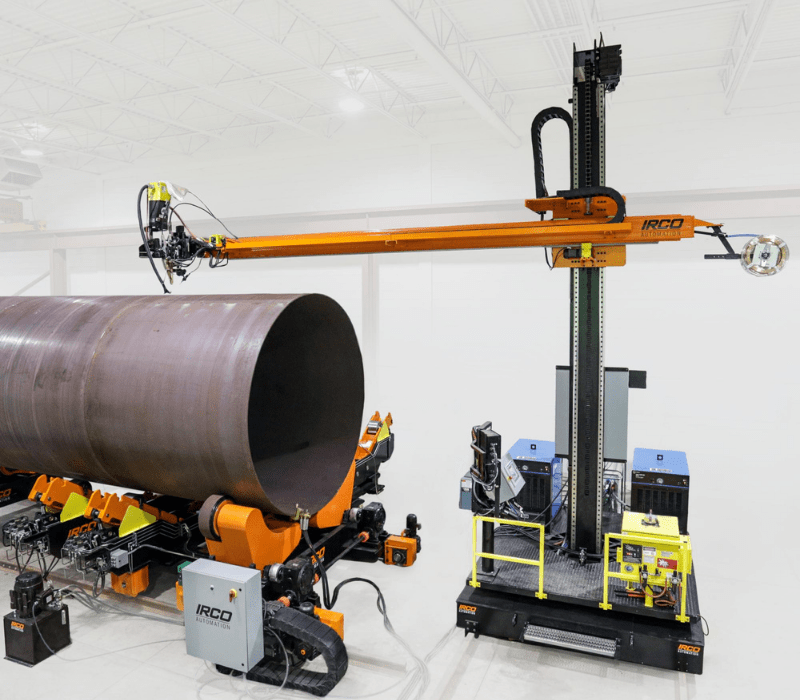

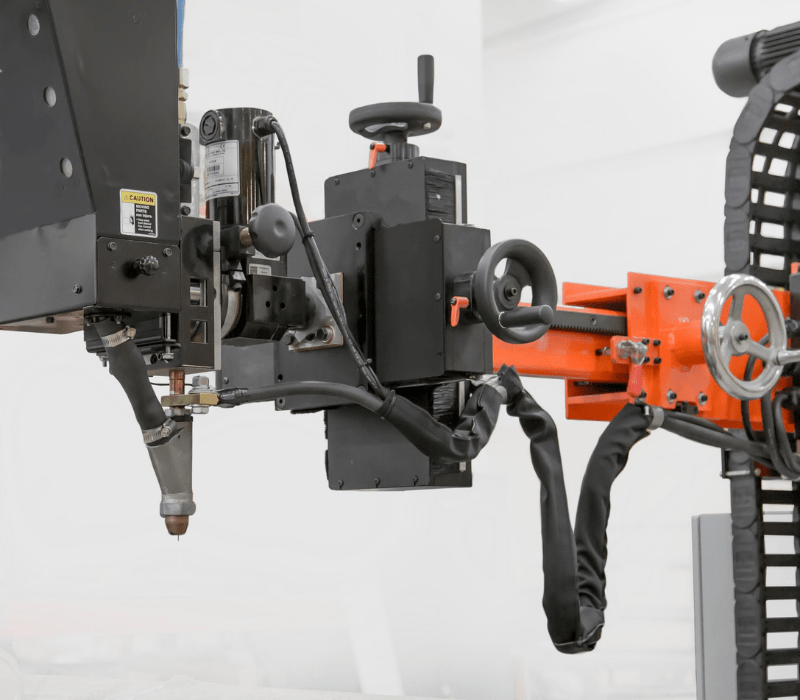

Positioning Equipment

Standard Products

IRCO Automation® offers a wide range of weld positioning equipment, as well as solutions involving fully integrated automatic welding systems. Our welding positioning equipment and design solutions can be found in action within the many industry sectors, such as machinery and attachment manufacturing, defense, aerospace, transportation, energy, and structural steel or bridge manufacturing.

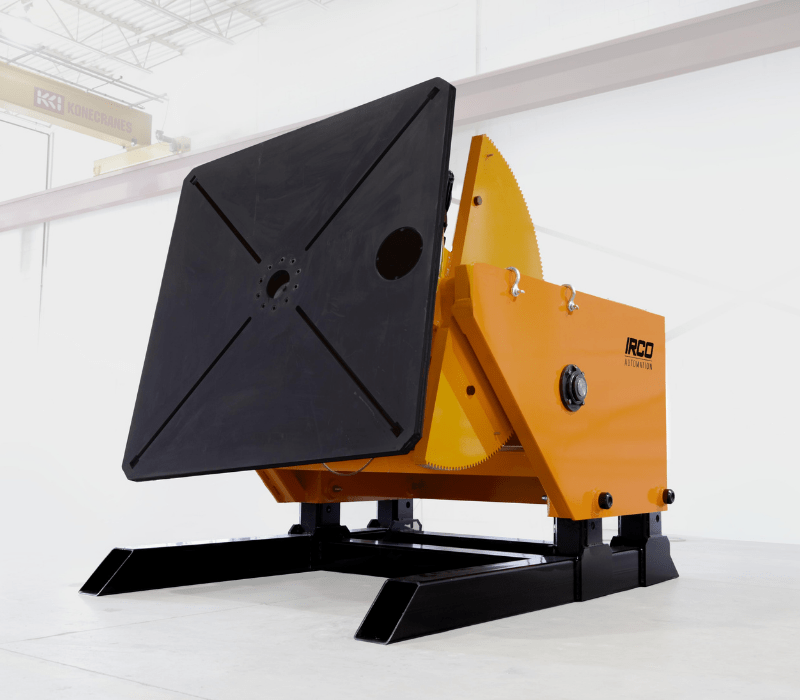

Customized Solutions

Our team specializes in creating solutions to lift, position, and weld large heavy elements and workpieces. If you're looking for a customized solution or bundled set of equipment for a specific project or growing line, let us design and build a solution that meets the demands of your process and weld positioning requirements.

Standard Products

IRCO’s expertise in the development of welding automation solutions resides in-house. Our team of welding, mechanical, electrical and controls engineers have years of experience implementing automation systems—underscored by CWB and CWI accreditations.